- Mob: +91 7977008918

- Email : office@yash-impex.com

- Home >

- Steel Plates >

- High Manganese Steel Plates

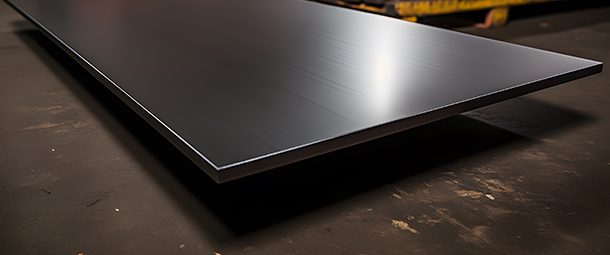

High Manganese Steel Plates

Looking for a steel capable of withstanding even the most demanding jobs? Look no further than our High Manganese Steel Plates. Known for its high strength and durability, these plates contain 11-14% manganese, granting them high impact and wear and tear resistance. What's even more striking is its work-hardening feature. No matter how many times it's impacted, it will become even stronger. It's almost like it lives under pressure!

These plates work best in environments in which wear and tear is a constant issue. With high-impact machines such as shot blast machines, rock crushers, and construction machines, our High Manganese Steel Plates will not falter. They have high toughness and durability, providing a working surface that will become ever harder with use and a resistant, strong core.

So, if dependability, durability, and high-performance matter, then our High Manganese Steel Plates have been designed to deliver that.

Wear Resistant Materials

WARRIORS ACRONI, X12, 11- 14 % MANGANESE PLATE

WARRIORS ACRONI, X12, 11- 14 % Manganese is a true Hadfield Austenitic Manganese steel for resistance to severe impact and abrasive wear. It is work hardening steel.

WORK HARDENING refers to the fact that the steel becomes harder and harder the more it is impacted or compressed.

The “Hadfield” grade has an original hardness of approximately 220 Brinell. With continued impact and /or compression it will surface harden to over 550 Brinell.It should be noted that only the outer skin surface hardens. The under layer remains highly ductile and tough. As the surface wears, it continually renews itself becoming harder and harder.

Manganese steel is austenitic steel which means it is non-magnetic. This property makes it useful in many applications such as bottom plates for lifting magnets - separator drum shells for magnetic materials - wear shoes on electric brakes etc

CHEMCIAL COMPOSITION

Typical Mechanical Properties

| Hardness (As Delivered) | Tensile Strength | Yield Strength | After work Hardening |

| 250 BHN | 1, 32,000 PSI Min | 90,000 PSI Min | 550 BHN |

Note: Actual field results may vary depending upon the application and overall conditions of use.

ADVANTAGES

STOCK PROGRAMME

| THK | WIDTH | LENGTH |

| 2mm | 0 - 1000mm | 0-2000mm |

| 4mm | 0 - 1000mm | 0-2000mm |

| 5mm | 0 - 1000mm | 0-2000mm |

| 06mm | 1000-2000 | 2000 - 4000-5000 |

| 08mm | 1000-2000 | 2000 - 4000-5000 |

| 10mm | 1000-2000 | 2000 - 4000-5000 |

| 12mm | 1000-2000 | 2000 - 4000-5000 |

| 16mm | 1000-2000 | 2000 - 4000-5000 |

| 20mm | 1000-2000 | 2000 - 4000-5000 |

| 25mm | 1000-2000 | 2000 - 4000-5000 |

| 32mm | 1000-2000 | 2000 - 4000-5000 |

| 40mm | 1000-2000 | 2000 - 4000-5000 |

why us

-

1

Ace quality Steel Products

We are an ISO certified company with exports spanning across the globe. Our long standing success is attributed to impeccable quality and the most comprehensive range of steel products we deliver.

-

2

Reasonable Pricing

We believe in cultivating long run business relationships will our clients. That’s why we offer the most competitive pricing in the industry.

-

3

On time, Every time

We have powerful sourcing network and can deliver products to any part of the globe. We will meet your requirements, on time, every time!