When you are investing your money into a new industrial project that requires installing new carbon steel pipe fittings, it becomes an immediate necessity to check the materials that will be used to lay those pipes, flanges, elbows, and more.

Carbon steel pipe fittings connect steel pipes to many applications used in construction projects. Therefore, it is of utmost importance to choose high-quality carbon fittings, and creating a difference between high-quality and low-quality fittings is more challenging than it sounds. There are several factors to consider while selecting carbon steel pipe fittings and the installer might get confused about which one to go for.

To make things easy for you, we have come up with a list of tips that will help you prioritize high-quality carbon steel pipe fittings in your manufacturing projects:

-

Prioritizing Cleanliness and Aesthetics

When you use conventional joining techniques that leave behind material build-up, tarnish, or threads that diminish the quality of your carbon steel pipe fittings then you must change your approach to them.

To prioritize the cleanliness and aesthetic quality of your pipe, you should use a battery-powered tool that presses your fitting onto the pipes and replaces the conventional methods of fitting. This new method keeps your pipe debris, grease, and rust-free for a long time.

-

Quality Materials and Testing

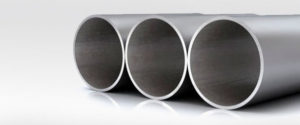

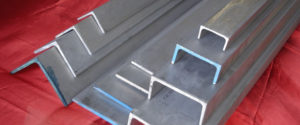

While selecting carbon steel pipes, the manufacturer has to consider the quality of the materials they are composed of. Different quality steels are available in the market and not all of them are desirable. To select a pipe of high quality certain markers are to be taken into crucial consideration such as corrosion resistance, strength, agility, and reliability in extreme temperatures. It is also crucial that each pipe must be under the supervision of a strict testing process to ensure its quality.

-

Perfect Dimension and Sizes

When a manufacturer is choosing corban steel pipe fittings for their construction work, it is essential to choose the correct size and dimension of the pipe. Neglecting this factor will lead to faulty pipe usage, either a short pipe or a leftover that has to be discarded.

Pipes of the correct size fill prevent leakages, rustiness, and other manufacturing issues.

-

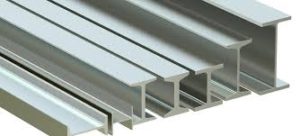

Advanced Manufacturing Process

Yes, each detail matters while making a carbon steel pipe fitting. And this starts at the beginning, with the production process of your pipes. Using advanced and new technologies to manufacture pipes will result in output that is high-quality and easy to function without any corrosion associated with conventional production processes.

Therefore, when you are choosing a manufacturer for your carbon steel pipe fitting supplier, make sure that they have qualified certifications and licenses such as ISO 9001, to ensure that they meet strict production requirements of the pipes.

-

Installation Speed and Application

The speed of installation of carbon steel pipe fittings is also an essential factor to consider when choosing a supplier. Modern technology can work in an environment to install these pipes.

And at the same time, your pipe’s end user should also be taken into account. Different sectors require different kinds of fittings. So considering them will help you select the right carbon steel pipe supplier.

Conclusion

To select a high-quality carbon steel pipe fitting, many factors mentioned above must be taken into consideration from the quality of materials to testing and inspection, and also the end-user or the industry. Take each aspect into account and select a supplier that meets all the said demands.